Insulated SIP Roof Panels and Wall Panels

RAYCORE's Structural Insulated Roof Panels and Insulated Wall Panels (SIPs) are NOT A SANDWICH PANEL SIP that consists of two sheets of OSB, glued to a solid foam core.

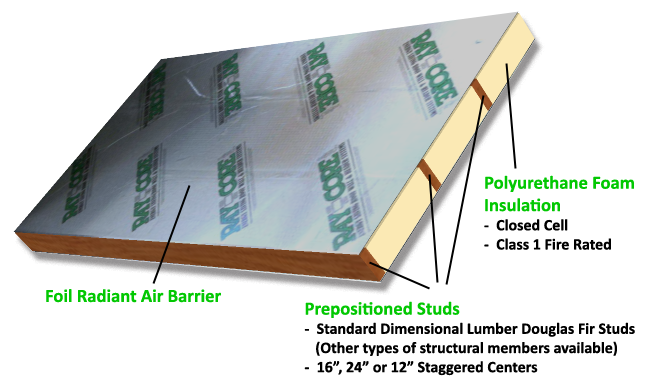

RAY-CORE SIPs ® are far superior - eliminating all the problems associated with traditional Sandwich Panel SIPs. RAYCORE takes the proven structural reliability of studs, adds a state-of-the-art custom blend of closed cell polyurethane foam insulation and wraps the panel with a foil radiant barrier to combine these three technologies into one strong, lightweight, structurally sound, labor saving and easy to use insulated SIP roof panel, insulated wall panel and insulated header framing panel system. So easy to use, even a DIY do-it-yourselfer can build with RAY-CORE SIPs ®!

RAYCORE Structural Insulated Panels ® (SIPs) - Over 30 years of manufacturing superior structural insulated panels, RAYCORE offers a lifetime warranty on all their SIP products.

Why is RAY-CORE so Smart?

- Easy to use Do-It-Yourself Friendly.

- No special design or engineering necessary.

- Exceeds or meets all codes.

- Affordable (on avg. only $1350.00 more than fiberglass).

- Extremely lightweight (no cranes necessary).

- Decrease utility bills by 60% or more.

- Least expensive per R-value inch insulation on the market. *

With benefits like these, it's no surprise RAY-CORE was Idaho's 2011 Business of the Year.

When Can I Use RAYCORE Insulated Roof Panels?

- Vaulted, Open-Beam Roof Applications (vented & non-vented)

- I-Joist Roof Systems

- Truss Roof Systems

- Conditioned Attic Spaces

- Adding insulation to an existing roof

When Can I Use RAYCORE Insulated Wall Panels?

If you can build it with sticks, you can build it with RAY-CORE SIPs ®. Conventional stick framing, preinsulated and in a panelized form. RAYCORE meets all codes for stick framing and are accepted in code jurisdictions throughout North America.

- New Construction

- Existing Structures

- Remodels

- Additions

- Adding Insulation to Exterior Walls

- Basement Wall Insulation Panels

- Floor Systems

- ... And Much More!

Utilizes Conventional Framing Practices

RAYCORE SIP roof panels and SIP wall panels combine three labor tasks into one smart panel system. This system utilizes conventional proven building materials: premium Douglas fir members, state-of-the-art foamed in place rigid polyurethane foam, and foil radiant barrier. This brilliant panel coupled with jobsite materials will meet all local standard building codes.

For code purposes, RAYCORE Structural Insulated Panels - SIPs, with integrated studs, are considered conventional framing and fall under the provisions of the IRC Section 6, when applicable to wall framing. (Section R610 does not apply, as RAYCORE SIP’s are not a “Sandwich panel” style SIP as defined by the IRC and regulated by that section.) No special code, No special ICC reports required.

Do-It-Yourself Friendly SIPs

From commercial to residential no other roof panel system offers a more do-it-yourself friendly process than RAY-CORE SIPs ™. With super lightweight panels and utilizing standard framing tools and practices, you can tackle the most difficult projects and use RAY-CORE SIP Panels. Learn More.

Very Affordable

RAYCORE is the most affordable structurally insulated panel on the market. This small investment will pay you back in less than three years and keep money in your pocket throughout your life. With returns like that you can’t afford to go without RAY-CORE roof panels on your next project.

Added to that, because of the exceptional R-value, tightness and performance of the RAYCORE Insulated Roof Panels and Insulated Wall Panels, the Heating and Cooling system will have to be downsized because of the reduced load. Often this results in a savings equal to the cost of the panels, in essence making them FREE!

RAYCORE's SIP Panels are the least expensive SIP panel per R-value inch on the market!

RAYCORE Insulated Roof Panels and Wall Panels Features:

- Foamed-In-Place Wood Studs

- High Density Closed Cell Polyurethane Foam

- Foil Radiant Vapor Barrier

- Easy To Use Dimensions

- Extremely Lightweight - No Cranes or Special Equipment Necessary to Move Panels

- Exceeds Or Meets All Codes - Considered Standard Stick Framing

- Least Expensive Per R-value Inch Insulated Panels On The Market!

RAYCORE SIP Panels Dimensions?

Standard Framing Thickness:

2x4 (3 ½”) – R26 *

2x6 (5 ½”) – R42

2x8 (7 ¼”) – R52

Standard Widths:

4 feet wide

Standard Lengths:

Precuts: 92 5/8, 104 5/8, 116 5/8 inches

Full: 8, 10, 12 feet

RAYCORE Polyurethane Foam

This state-of-the-art custom blend of high density closed cell polyurethane foam not only produces some of the highest R-values available, it has a low perm rate and will not retain or allow moisture to pass through it, so no problems with condensation or mold and mildew. It also ensures an airtight structure. Further, it produces all of these benefits while maintaining a Class 1 Fire Rated standard. Class 1 means that the foam will not sustain a flame. Far, far superior to polystyrene foam, RAYCORE’s quality control standards will not settle for less.

Foil Radiant Air Barrier

This paper thin high-tech foil radiant barrier, similar to an emergency heat blanket, helps to reflect the outside temperatures out and the inside temperatures in on any structure.

Only RAYCORE combines these advanced technologies into one energy saving SIP panel.