RAYCORE INSULATED ROOF PANEL INSTALLATION

RAYCORE Insulated Roof Panels are designed to meet the needs of energy conscience builders and homeowners. RAYCORE Roof Panels are a highly-insulated and energy efficient, green home construction, energy saving solution that will help to meet the needs of conventional construction along with the unique roof insulation needs of Log, Timber Frame, Post & Beam, Straw Bale, and other types of homes. RAY-CORE SIPs are also a low cost “no-brainer” solution for those looking to add roof insulation to an existing structure.

RAY-CORE Insulated Roofing Panels are a low-cost “win-win” solution for large commercial roof projects, providing a competitive solution to offer a bid that cannot be beat and increasing the builder's bottom line at the completion of the project.

The RAYCORE Insulated Roof Panels can be used on an engineered truss roof. Should you wish to insulate your roof in an other manner, see the "Best Practices" section for “Rafters, Trusses and Attic Insulation”.

Note:

Installation shall be in accordance with manufacturer’s published instruction, utilizing conventional construction methods and practices. Furthermore, all methods and practices should comply with engineers or architect’s specifications, and conform to national, state, and local building code requirements. No recommendations in this guide should supersede those specifications and requirements. Deviations from standard and conventional building methods and practices should be calculated, specified, signed and sealed by a licensed professional engineer or architect.

Step-By-Step Insulated Roof Panel Installation

Step 1.

Preparation: Prepare roof surface for panels to be installed. For exposed beam ceiling applications, typically tongue and groove decking or other finishes are applied prior to placement of panels. Other finish materials may also be specified.

For finished drywall or unexposed beam applications, plywood or OSB may be specified for decking prior to panel installation, but if not required, roof panels can be installed directly onto rafters or trusses.

Best Practices: Spread 6 mil visqueen, roofing felt or other vapor barrier over entire roof decking surface under panel. If no decking is specified, underside of panels should be taped with 3” vapor proof tape, and all joints checked and filled for a tight seal, to prevent air infiltration or moisture transfer.

"Open Beam" Ceiling Installation

Step 2.

Application of Panels: Place the RAYCORE Insulated Roof Panels on roof. The roof panels are typically applied perpendicular to the rafters or trusses, although some applications have called for them to be installed vertically. Specify application at the time of ordering the panels for accurate estimating purposes.

Sealing: To ensure an air-tight joint, apply a continuous bead of foam friendly construction adhesive, (such as Liquid Nails or equal) to all edges, between the RAY-CORE SIPs ® panels and all other framing members to seal joints. Push panels firmly together, leaving no gaps and assuring the panels are tight and square. Attach to roof as instructed in Step 3. Further sealing, if required, can be performed once the panels are permanently attached.

Apply Continuous Bead of Adhesive to Seal Roof Panel Joints

Step 3.

Attach Panels: Use 5”- 12” panel screws to fasten panels to rafters and/or decking, drilling through the RAYCORE insulated roof panel’s integrated structural members (“studs”) found 16” or 24” oc. Self-driving torque screws are recommended. Based on the framing and materials that will support the panels, some applications may require that the RAYCORE roof panels structural members span from rafter to rafter. When sufficient structural material will support the panels, this may not be required. Use screw schedule per engineer or architect’s requirements. Penetration depth shall be dictated by local code. RAYCORE generally recommends 9—12 screws per panel, (Screws can be supplied by RAYCORE) with at least 2” of penetration.

Step 4.

Sealing & Taping: Sealing the envelope and eliminating air infiltration is critical to the energy-saving performance of the RAY-CORE roof panels and will prevent vapor transference. Fill any open joints, cracks or voids, and penetrations with canned polyurethane foam (Great Stuff or equal) and once cured, remove any excess. Smaller voids can be sealed with flexible caulk.

To get the best performance and ensure that there be no air infiltration and resulting vapor transference, all seams, joints to additional framing members, and penetrations should be sealed with vapor proof tape. This step is required. (FSK tape can be supplied by RAYCORE)

Although care should be taken to prevent damage of the panels foil facing when handled, small tears, occasional bumps or gouges may occur. The panels can be simply repaired by filling with canned polyurethane foam or by applying vapor proof tape to seal.

Taping of Panel Joints is a Critical Step!

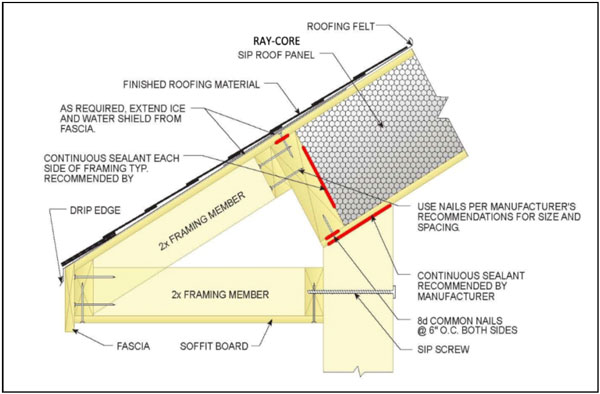

Extending Roof Overhangs or "Eaves"

Extending Roof Overhangs or “Eaves”:

Roof overhangs or “eaves” can be extended either by carrying the panel out as the overhang to the fascia or by framing the eaves after the installation of the roof panels and before sheathing the roof. The detail to your right demonstrates one way to complete this installation.

Extending Roof Overhangs or "Eaves" with RAYCORE Insulated Roof Panels

"Hot" Roof (Unvented) Application

"Hot" Roof - Sheathing Applied Directly To Panels

Most shingle manufacturers today warrant their products for unvented roof application when properly installed, but it is recommended that you check with your shingle manufacturer to assure that this is an approved application. For unvented applications, simply apply roof deck materials, such as plywood or OSB, directly on top of the properly sealed and taped RAYCORE SIP Roof Panels, overlapping the joints in the panels with the joints of the decking to produce a strong base. Ice and water shield and/or roofing felt on top of the panels should be installed over the panels and sheathing. Proceed with the shingling process in a conventional and code approved manner. As always, check with the roofing material manufacturer, your roofing specialist, your engineer/architect and local code officials for proper application of roofing materials.

Best Practices: Ice and water shield, roofing felt or membrane should be installed on top of the panels and sheathing and builder should ensure a water/moisture proof seal.

"Cold" Roof (Vented) Application

Should your project require a vented roof, this can be achieved by placing 2x2 or 2x4 battens or “sleepers” to the top of sealed and taped RAYCORE Insulated Roof Panels, screwed to the integrated structural members (“studs”) included in the RAY-CORE SIPs ®. Ice and water shield and/or roofing membrane should be installed on top of the panels and the builder should ensure a water/moisture proof seal. Finish roof in a conventional and code approved manner. As always, check with the roofing material manufacturer, your roofing specialist, your engineer/architect and local code officials for proper application of roofing materials.

Metal Roof Application

When using a metal roofing it may be possible to apply the metal roofing directly to the sheathing over properly taped and sealed RAYCORE roof panels without requiring additional battens. Roofing manufacturer and code official approval is required. Ice and water shield must be installed on top of the sheathing and your builder should ensure a water/moisture proof seal. Finish roof in a conventional and code approved manner. Check with the roofing material manufacturer, your roofing specialist, your engineer/architect and local code officials for approval and proper application of roofing materials.

Best Practices: Ice and water shield should be installed on top of the panels and builder should ensure a water/moisture proof seal.

Click Below for More RAYCORE SIPs "How To"

Wall Panel Installation Guide

Best Practices

Wiring, Plumbing and Ventilation

Attaching Wall Panel to a Concrete Wall or Slab

Additional Installation Procedures & Documents You Might Find Useful

Print or Save A Copy Of the RAY-CORE SIPs ™ Installation Guide