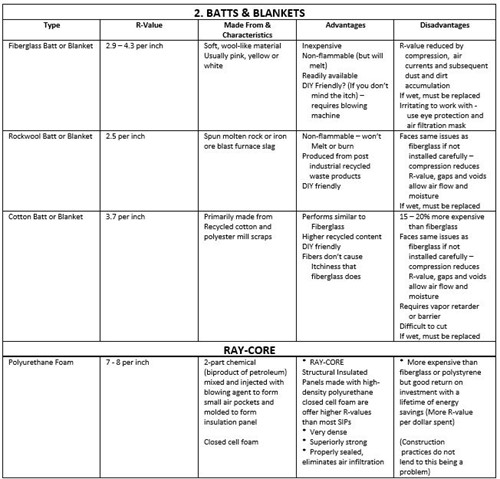

Compare Insulation - Structural Panel to Fiberglass, Rockwool and Other Batt & Blanket Insulations

Our last post we compared Structural Panel Insulation (SIP) to loose-fill insulation, in hopes to provide an easy way for you to make comparisons. To continue with this theme, today we are going to explore Batt and Blanket Insulation in comparison to RAYCORE structural panel insulation by looking at R-value per inch and some of the advantages and disadvantages. If you take a careful look at the table below you will see that in comparison to fiberglass and wool batt and blanket insulation, RAYCORE’s structural panel insulation (SIP) is far superior. The panelized form offers the added benefit of framing, insulation and wrap all in one structural panel and one step.

Compare RAYCORE Structural Panels to Other - R-Values, Characteristics, Advantages & Disadvantages

To learn more now about RAY-CORE SIPs ™ , visit our website and see how RAYCORE Structural Panels will pay you back in savings for the lifetime of your home

By Email at: info@raycore.com or by Phone: 1.877.552.2440 or…