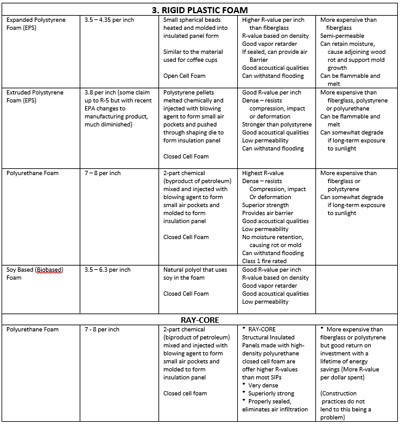

Compare Insulation - SIP Panel to Other Foam Insulations

SIP Panel insulation is offered in several different forms. In this post, part 3 of a series of 6 different types of insulation on the market, we discuss the difference between rigid plastic foam insulations. In the table below we compare various foams R-values, characteristics and advantages and disadvantages to that used in RAYCORE's structural insulated panels. Just one more step in making the decision when purchasing a SIP panel for your next home. RAY-CORE SIPs ™ uses only the best... super insulating closed cell polyurethane foam insulation in their structural insulated panels. Different than sandwich panel SIPs, RAYCORE SIP panels take the tried and true construction practice of using studs, fills the voids with high R-value foam, adds a radiant barrier all wrapped up in a modular, lightweight structural panel with superior strength.

Compare RAYCORE SIP Panels to Other - R-Values, Characteristics, Advantages & Disadvantages

If you would like to learn more now about RAYCORE's SIP panels, visit our website at raycore.com or

By Email at: info@raycore.com or by Phone: 1.877.552.2440 or…