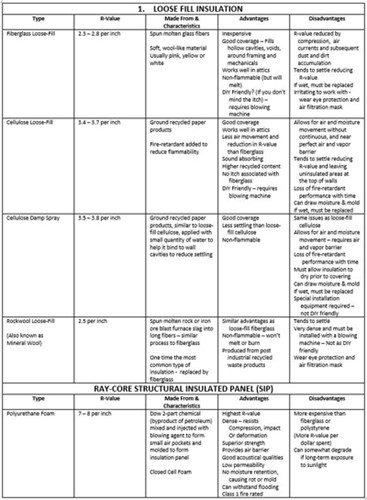

Compare Insulation - Structural Insulated Panel - SIP to Cellulose and Other Loose Fill Insulation

Comparing Structural Insulated Panel (SIP) to other forms of insulation, can be a long and tedious process, so we thought we would do the work for you. Our previous post broke insulation down into 6 categories. To get a better picture of how different insulations compare, the next 6 posts will take these categories and further break them down identifying some of the more common insulation products, compare insulation R-value per inch, and discuss some of the advantages and disadvantages. Take a look at the table below and compare the superior qualities of RAYCORE’s Structural Insulated Panel (SIPs)

Compare RAYCORE Structural Insulated Panel - SIP to Other - R-Values, Characteristics, Advantages & Disadvantages

See why you must consider RAYCORE Structural Insulated Panel - SIP when building your next home.

To learn more, visit our website and see why structural insulated panel construction with RAY-CORE SIPs ™ is the smart choice

By Email at: info@raycore.com or by Phone: 1.877.552.2440 or…